ABB PHARPSFAN03000 Fan Best Application Solutions in Industrial Control Cabinets

ABB PHARPSFAN03000 Fan Best Application Solutions in Industrial Control Cabinets

Industrial automation becomes increasingly complex, and therefore engineers must select cooling components that ensure stable operation under continuous workloads. Among various cooling devices, the ABB PHARPSFAN03000 industrial fan stands out because it provides efficient airflow, dependable durability, and consistent performance. Although the control cabinet environment varies from one application to another, engineers can still create universal strategies that allow the fan to deliver maximum value. This article explores the best application solutions for the ABB PHARPSFAN03000 inside industrial control cabinets while offering practical guidance for layout planning, system optimization, and long-term reliability.

Furthermore, because many automation manufacturers seek components that integrate smoothly with existing ABB modules, the PHARPSFAN03000 becomes a preferred choice. Therefore, engineering teams benefit from understanding how to incorporate this fan into diverse cabinet designs. Throughout this blog, every section includes smooth transitions so readers can follow each technical point effortlessly.

1. Understanding the ABB PHARPSFAN03000 Fan in Industrial Environments

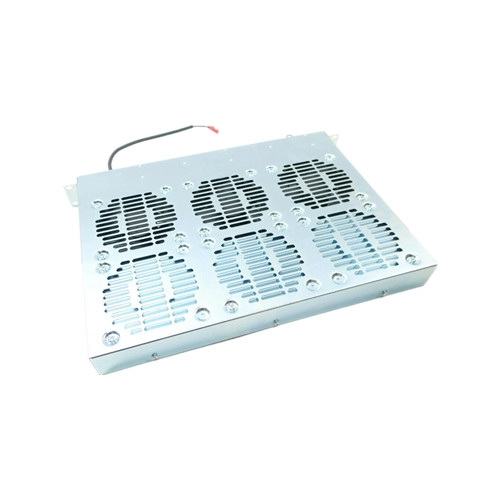

Before exploring advanced cabinet strategies, engineers should first gain clarity regarding the fan’s intended function. The ABB PHARPSFAN03000 industrial fan improves airflow circulation inside enclosed automation spaces. Moreover, it helps maintain temperature balance near PLC modules, power units, relay banks, communication cards, and high-density circuit assemblies. Since modern automation panels generate substantial heat, the fan reduces thermal stress and stabilizes long-term operation.

Although control cabinets differ in size, layout, and equipment density, this fan adapts to them because it provides steady cooling without unnecessary complexity. In addition, its compact structure enables flexible placement while its airflow output supports cabinets that include ABB power modules or Bailey series components often used by integrators.

2. Why Proper Cooling Matters in Industrial Control Cabinets

Reliable airflow provides more than temperature reduction. In fact, effective cooling prevents unexpected shutdowns, protects sensitive electronics, and extends hardware lifespan. Moreover, since industrial production lines run continuously, even minor overheating may cause significant production delays. Consequently, engineers must design ventilation that aligns with the heat load of each cabinet.

The ABB PHARPSFAN03000 becomes especially valuable because it delivers controlled airflow rather than turbulent and uneven circulation. Furthermore, by supporting stable internal pressure, it helps dust filters work more effectively. Therefore, a well-implemented cooling strategy maintains both thermal and environmental cleanliness.

3. Key Characteristics That Make PHARPSFAN03000 Ideal for Control Cabinets

To develop the best application solutions, engineers should consider the features that make this fan suitable for industrial cabinet integration. Although different models exist, the PHARPSFAN03000 consistently offers benefits such as:

3.1 Compact Dimensions

The fan’s small footprint allows placement near heating points. Additionally, it fits into narrow spaces that often appear in high-density control panels.

3.2 Energy Efficiency

Because energy costs increase globally, an efficient fan reduces operational expense. Furthermore, it decreases heat without demanding large electrical loads.

3.3 Continuous-Duty Stability

Industrial environments demand uninterrupted operation. Therefore, the fan’s design supports long-term, stable usage even under challenging environmental conditions.

3.4 Low Noise Output

Although noise may not seem critical, quieter cooling solutions improve workplace comfort. Moreover, low vibration minimizes stress on nearby components.

3.5 Compatibility with ABB System Architectures

Since many integrators use ABB modules, the PHARPSFAN03000 integrates smoothly with cabinets containing ABB PLCs, controllers, and power hardware.

4. Planning the Best Cabinet Layout for PHARPSFAN03000

The next important step involves positioning the fan in a way that enhances airflow. Although cabinet environments vary, several universal principles apply.

4.1 Place the Fan Near Hotspot Zones

Heat typically concentrates near:

-

Power supply modules

-

CPU units

-

Communication modules

-

Servo drivers or VFD interfaces

Therefore, engineers place the PHARPSFAN03000 close to these components while ensuring the airflow direction pushes heat toward outlet vents.

4.2 Always Consider Airflow Path Efficiency

A cabinet must include:

-

A defined air entry point

-

A clear air exit path

-

Minimal airflow obstruction

Moreover, cable bundles often block airflow, so organizing them with structured cable routes dramatically improves cooling efficiency.

4.3 Allow Balanced Intake and Exhaust

Effective cooling requires both intake and exhaust fans. Therefore, engineers often pair the PHARPSFAN03000 with a filter module or secondary exhaust fan. Because balanced airflow prevents air stagnation, system temperature remains stable.

5. Environmental Considerations That Increase Cooling Effectiveness

Because real-world environments differ, engineers must adapt each installation of the PHARPSFAN03000.

5.1 Ambient Temperature

If the cabinet operates in high-temperature environments, airflow must be stronger. Therefore, engineers may increase the number of fans or combine the PHARPSFAN03000 with heat-exchangers.

5.2 Dust and Particulates

Dust accumulation restricts airflow. Consequently, filter maintenance becomes essential. Regular cleaning ensures the fan remains efficient.

5.3 Humidity Management

Humidity affects electronics. Although the fan does not dehumidify air, good airflow prevents moisture pockets from forming. Therefore, fans enhance cabinet dryness.

5.4 Vibration Zones

Some factory environments expose cabinets to mechanical vibration. Fortunately, the PHARPSFAN03000 withstands moderate mechanical stress, but engineers still place vibration dampers for long-term reliability.

6. Best Application Strategies for Specific Cabinet Types

6.1 High-Density PLC Cabinets

Because these cabinets contain multiple CPU modules and I/O banks, they generate substantial heat. Therefore, the PHARPSFAN03000 becomes essential for stabilizing temperature near processor modules. Moreover, placing the fan near mid-height improves vertical airflow distribution.

6.2 Power System Cabinets

Power supply units produce localized heat. Therefore, engineers mount the fan near the transformer or switching module while guiding hot air toward upper exhaust vents.

6.3 Communication Network Cabinets

Switches and communication gateways generate moderate heat but require extremely stable temperatures to avoid signal errors. Consequently, a stable airflow plan using PHARPSFAN03000 ensures consistent network performance.

6.4 Mixed-Component Automation Cabinets

These cabinets combine PLCs, drives, communication units, and relays. Because heat distribution varies, engineers use multiple fans. Furthermore, fans may be assigned to specific heat zones to create targeted cooling.

7. Installation Recommendations for Maximum Performance

7.1 Ensure Secure Mounting

Although the fan is lightweight, proper mounting ensures vibration control. Therefore, engineers use bracket support and vibration pads.

7.2 Maintain Clearance Around the Fan

Airflow depends on unobstructed circulation. Therefore, avoiding cable blockage improves performance.

7.3 Use High-Quality Wiring for Fan Power

Stable power delivery ensures consistent airflow. Moreover, engineers should avoid routing the fan’s wiring near high-EMI cables.

7.4 Implement Routine Maintenance Cycles

Because dust and debris reduce airflow, regular cleaning keeps the fan running at full capacity.

8. Thermal Testing and Performance Validation

Engineers should always test the cabinet after installation. While performing thermal analysis, they observe:

-

Temperature near CPU modules

-

Airflow direction effectiveness

-

Hotspot elimination

-

Filter condition

-

Fan rotational speed consistency

Because these observations confirm whether cooling meets operational expectations, adjustments become easy to implement.

9. Optimizing PHARPSFAN03000 for Long-Term Reliability

Long-term performance depends on:

9.1 Choosing the Correct Operating Voltage

Stable voltage supply prevents overheating of the fan motor.

9.2 Cleaning Filters on Monthly Cycles

Since dust reduces efficiency, consistent maintenance enhances airflow.

9.3 Monitoring Temperature Trends

Engineers may install temperature sensors that track performance over time. Therefore, they can detect early failure signs or airflow reduction.

9.4 Combining Passive and Active Cooling

Using heat-sinks along with the fan creates hybrid cooling that improves stability.

10. Example Applications Across Industries

10.1 Power Generation Facilities

Control cabinets in power plants operate continuously. Therefore, the PHARPSFAN03000 provides steady cooling for mission-critical controllers.

10.2 Chemical Processing Lines

These environments generate ambient heat. Consequently, strong cabinet cooling prevents thermal damage to PLCs.

10.3 Automotive Manufacturing Cells

Robotic systems require stable controllers. Therefore, cooling fans keep drive cabinets within safe temperature limits.

10.4 Food and Beverage Production

Cabinets often operate near warm machinery. Because the PHARPSFAN03000 provides consistent airflow, it maintains stable performance despite environmental variations.

11. Conclusion

The ABB PHARPSFAN03000 industrial fan provides reliable, efficient, and intelligently controlled airflow for diverse industrial control cabinet environments. Moreover, because it integrates smoothly with ABB system architectures, engineers often select it to stabilize temperature around PLC modules, power units, and communication cards. Whether the cabinet requires targeted cooling for hotspots or broad circulation for densely packed electronics, the PHARPSFAN03000 delivers a practical solution.

Furthermore, by combining strategic placement, balanced airflow paths, environmental adjustments, and regular maintenance, engineering teams can significantly extend equipment lifespan. As industrial automation continues to advance, reliable cooling becomes more important, and therefore a professional solution such as the PHARPSFAN03000 remains essential for protecting system assets and ensuring long-term operational success.