Five Essential Specifications for ABB PHARPSFAN03000 Procurement

Introduction

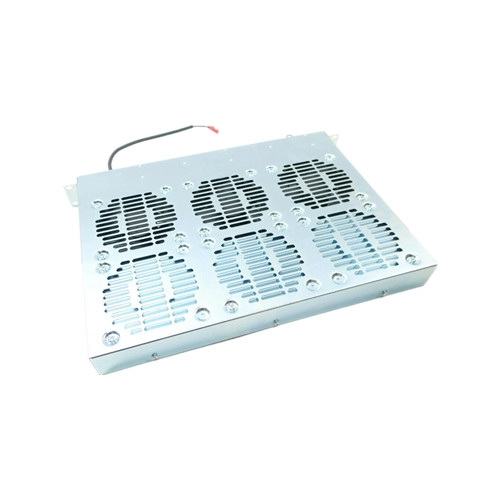

When selecting industrial cooling solutions, understanding the critical specifications of the ABB PHARPSFAN03000 is essential. This high-performance fan supports optimal thermal management for ABB control systems, including PLCs, HMIs, and power modules. Its performance ensures system stability, reliability, and energy efficiency. In this article, we explore the five key specifications every buyer should evaluate before purchasing the PHARPSFAN03000. Detailed analysis of airflow, voltage, noise, durability, and compatibility helps operators make informed decisions, ensuring long-term operational success.

1. Airflow and Cooling Capacity

Airflow represents the most crucial indicator of a fan’s performance. The PHARPSFAN03000 delivers consistent airflow at high speeds, ensuring effective cooling for ABB automation modules. Its rotation speed of up to 2800 RPM provides sufficient ventilation to prevent hotspots and maintain uniform temperatures across control panels. Buyers should evaluate the fan’s cubic feet per minute (CFM) rating, as this determines how efficiently it can dissipate heat. Compared to standard industrial fans, the PHARPSFAN03000 offers superior airflow precision, which reduces thermal stress on electronic components and enhances system reliability.

2. Voltage and Electrical Compatibility

Voltage and power requirements form another critical factor. The PHARPSFAN03000 operates at AC 230V with a frequency of 50/60Hz, aligning with common industrial standards. Ensuring compatibility with facility power supply prevents electrical failures and reduces installation issues. Buyers must verify voltage ratings to maintain safe and efficient operation. Additionally, the fan’s low power consumption ensures energy efficiency, reducing operational costs while supporting sustainable industrial practices. Compared to generic fans, this ABB model minimizes energy wastage while delivering consistent cooling.

3. Noise Level and Acoustic Performance

Noise and vibration impact both operational comfort and electronic reliability. The PHARPSFAN03000 operates below 55 dB(A), significantly quieter than many standard industrial fans. Reduced noise minimizes acoustic disturbances in facilities and prevents vibrations that could damage sensitive electronic components. Buyers should evaluate decibel levels and vibration performance, as these factors influence long-term system stability. Low-noise operation ensures a safer and more comfortable working environment while maintaining optimal module performance.

4. Durability and Maintenance Requirements

Durability directly affects operational lifespan and maintenance costs. The PHARPSFAN03000 features reinforced motor housings, high-quality blades, and robust bearings that withstand high temperatures, dust, and vibration. Its modular design allows quick installation and replacement, minimizing downtime. Buyers should assess maintenance intervals, material quality, and environmental tolerance. Unlike generic fans, the PHARPSFAN03000 maintains high performance in harsh conditions, providing reliable, maintenance-efficient operation that prolongs system life and reduces service costs.

5. Compatibility with ABB Control Systems

The fifth key factor is compatibility. The PHARPSFAN03000 integrates seamlessly with ABB PLCs, HMIs, power modules, and redundant systems. Its airflow design matches ABB module layouts, preventing thermal hotspots and optimizing performance. Buyers must confirm the fan’s compatibility with the intended system to ensure efficient thermal management. Using ABB-certified fans reduces installation complexity and guarantees reliable cooling performance, whereas generic fans may require additional adapters or produce uneven cooling.

Practical Insights and Best Practices

In addition to evaluating specifications, buyers should consider installation practices, operational environments, and monitoring routines. Properly installing the PHARPSFAN03000 ensures maximum airflow efficiency and minimal vibration. Regular inspection and cleaning maintain optimal performance and extend fan lifespan. Integrating multiple fans in high-heat environments enhances cooling redundancy, preventing system downtime. Operational feedback from facilities using ABB modules confirms that adherence to these best practices significantly improves system reliability and reduces energy consumption.

Conclusion

In conclusion, the ABB PHARPSFAN03000 offers unmatched performance, reliability, and energy efficiency when procured with attention to the five key specifications: airflow, voltage, noise, durability, and system compatibility. Understanding these indicators ensures optimal fan performance, reduces maintenance requirements, and enhances operational safety. Buyers who select the PHARPSFAN03000 with these criteria in mind benefit from superior thermal management, extended module life, and cost-efficient industrial operation. Standardizing this fan across ABB systems guarantees consistent cooling and long-term reliability for automation installations.