ABB PHARPSFAN03000 — Detailed Specifications & Selection Guide (Engineers’ Must-Read)

ABB PHARPSFAN03000 — Detailed Specifications & Selection Guide (Engineers’ Must-Read)

When engineers choose a cabinet cooling fan, they demand clarity, performance, and longevity. Therefore, this guide explains the ABB PHARPSFAN03000 specifications and helps you select the right unit for your application. First, I describe the key technical parameters. Then, I walk through mechanical and electrical considerations. Next, I compare mounting and airflow strategies. Finally, I cover maintenance, testing, and reliable sourcing. Consequently, you will complete maintenance planning, procurement, and integration with confidence.

1. Why the PHARPSFAN03000 matters

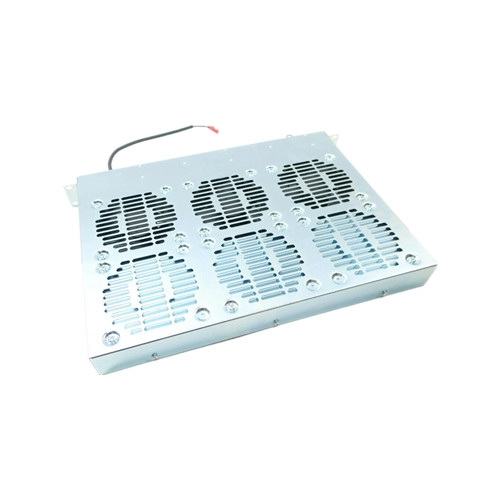

First, cooling affects electronic reliability. Electronic modules suffer when temperature climbs, and heat accelerates failure mechanisms. Therefore, you should design cabinet airflow proactively. The PHARPSFAN03000 fills that role by providing reliable forced convection in ABB and compatible cabinets. Moreover, the fan delivers consistent airflow while balancing noise and power use. In short, the PHARPSFAN03000 reduces thermal stress and increases mean time between failures.

2. High-level technical overview

Below, I summarize the main technical areas you need to check when evaluating the PHARPSFAN03000.

-

Airflow (CFM / m³/h): The fan pushes a specified cubic feet per minute (CFM) at free-air conditions and at typical static pressure when installed. Therefore, compare CFM values against your cabinet’s required heat removal rate.

-

Static pressure: The fan sustains airflow against cabinet filters and ducts. Consequently, higher static pressure capability improves actual delivered airflow.

-

Power consumption (W / V): The motor draws rated power at the nominal voltage. Thus, verify power rail capacity and inrush current.

-

Noise level (dB(A)): The fan produces measured sound pressure levels. Therefore, consider dB ratings for control room comfort.

-

Bearing type & MTBF: The fan uses industrial bearings that determine service life and maintenance interval. Consequently, choose a bearing style that suits continuous operation.

-

Ingress Protection (IP) & material: The housing and rotor resist dust and contaminants to a rated level. Therefore, IP ratings matter for harsh environments.

-

Connector / wiring: The fan includes standard connectors or pigtails. Therefore, verify compatibility with your cabinet harness.

3. Detailed electrical specifications

First, confirm nominal voltage. The PHARPSFAN03000 commonly supports 24 VDC or 115/230 VAC variants. Consequently, you must order the correct electrical version for your installation. Next, check maximum current draw and inrush current. Because many control racks use shared supplies, inrush can trip upstream protection. Therefore, specify soft start, staggered fan startup, or larger supply margins where needed.

Moreover, verify any built-in protection features. For example, the fan may include thermal cutoff or reverse-polarity protection. In addition, some models provide tachometer feedback for speed monitoring. Therefore, if you require predictive maintenance, select the version with tach output.

Finally, check PWM or voltage control compatibility. If you plan to vary fan speed for noise or thermal control, ensure the fan accepts PWM signals or voltage control within the expected range. Consequently, you enable controlled cooling that reduces noise and energy use.

4. Mechanical and airflow characteristics

First, understand the geometry. The PHARPSFAN03000 has a compact frame that fits standard ABB cabinet slots. Therefore, you should measure mounting clearances and ensure free inlet and outlet paths. Next, consider blade design. The fan uses engineered blades to maximize airflow at lower RPM, and therefore it reduces noise while maintaining performance.

Also, examine directionality and ducting. In many cabinet layouts, you will push air from front to rear, whereas other layouts require bottom-to-top flow. Therefore, determine the correct orientation before installation. Moreover, use baffles or plenums to prevent recirculation. Consequently, you will minimize hot spots and equalize temperature distribution.

Additionally, measure expected velocity and turbulence. Turbulent flow increases heat transfer locally, but it also promotes uneven cooling. Therefore, model airflow including filter resistance to predict actual component temperatures.

5. Mounting, vibration, and structural integration

Mount fans on rigid panels to avoid vibration transfer. First, use compliant grommets where necessary, and then torque mounting screws to specified values. Because vibrations shorten bearing life, confirm vibration tolerance under operating conditions. Next, isolate fans from sensitive sensors and drives to prevent noise coupling. Therefore, keep cabling and conduit separate from vibration sources.

Also, confirm shock rating. In heavy-duty installations, mechanical shock can shorten fan life. Therefore, choose reinforcement or shock mounts for mining, shipboard, or mobile applications. Finally, check accessibility for replacement. Install fans where technicians can remove and replace units quickly during scheduled maintenance.

6. Bearing types, expected life, and maintenance

The fan may use sleeve bearings, ball bearings, or fluid dynamic bearings. Each type offers tradeoffs:

-

Sleeve bearings deliver low cost and quiet operation, yet they require proper orientation and regular replacement.

-

Ball bearings handle higher temperatures and vibrations, and therefore they suit continuous industrial use.

-

Fluid dynamic bearings provide long life and low noise, and thus they deliver premium reliability.

Consequently, when you specify the PHARPSFAN03000, choose a bearing type that matches runtime, ambient temperature, and vibration profile. Moreover, confirm MTBF numbers and require manufacturer test data where necessary. Finally, establish a replacement interval and include fans in preventive maintenance plans.

7. Environmental ratings and suitability

First, check IP rating and material compatibility. For dusty or corrosive atmospheres, choose fans with dust seals and corrosion-resistant alloys. Second, verify operating temperature range. If ambient temperatures exceed nominal ratings, add cooling redundancy or derate the fan.

Also, consider altitude. At higher elevations, air density drops and the fan delivers less cooling. Therefore, specify fans with increased CFM or add additional units for altitude compensation. Finally, include humidity and condensation mitigation where condensation may affect electrical contacts. Consequently, apply conformal coatings or desiccant measures inside cabinets where necessary.

8. Thermal sizing and selection method

Engineers must size fans to remove heat equal to or greater than the cabinet’s heat load. First, calculate total heat generation (W) from all installed electronics. Then, convert watts to required airflow using simple heat transfer relationships, for example:

-

Q=m˙⋅cp⋅ΔTQ = \dot{m} \cdot c_p \cdot \Delta T (where Q equals heat in watts, m˙\dot{m} is mass flow, cpc_p is specific heat, and ΔT\Delta T is allowable temperature rise).

However, most engineers use simplified conversions: each 1 CFM of airflow removes roughly 0.5–1.0 W for small temperature deltas in ventilated cabinets. Therefore, select a fan or combination of fans that meet the CFM requirement at your cabinet’s expected static pressure. Moreover, include margins for filter loading and seasonal extremes.

9. Control strategies and fan redundancy

First, implement staged cooling. Start with a primary fan at low speed, and then add secondary fans when temperature thresholds trigger. Consequently, you reduce noise and extend fan life. Second, design redundancy: use N+1 arrangements where one backup fan runs only when others fail. Therefore, redundancy prevents single-point failures in critical systems.

Also, implement speed control through thermostats, PLC outputs, or external controllers. Because PWM control reduces energy use, you can operate fans at lower speeds during mild conditions. Finally, include fan status monitoring and integrate tachometer signals into SCADA. Therefore, maintenance teams receive alerts before failures occur.

10. Testing, commissioning, and verification

During commissioning, measure airflow, static pressure, and cabinet internal temperatures. First, verify that the actual CFM meets design targets after installing filters and cable harnesses. Then, perform thermal soak tests under full load for several hours. Consequently, you confirm thermal stability and identify hot spots. Moreover, log temperature sensors and tachometer readings to validate the control strategy.

Also, test fan failure scenarios. Simulate a single fan loss and verify alarm logic and redundancy actions. Therefore, you ensure the system responds correctly to component faults and protects critical modules.

11. Procurement, spares, and lifecycle planning

Specify original-equipment or authorized equivalents only. First, require manufacturer certificates and part traceability to prevent counterfeit components. Second, procure spares sized to permit hot-swap replacement. Consequently, you reduce downtime during scheduled and unscheduled maintenance. Third, include fans in asset management databases and schedule replacements based on runtime hours and vibration data.

Moreover, source fans from trusted suppliers who provide technical datasheets and test reports. For example, Wuhan Yuli Automation Technology Co., Ltd. stocks ABB parts and offers verification services for PHARPSFAN03000 units. Therefore, leverage authorized vendors to ensure part authenticity and warranty support.

12. Common failure modes and mitigation

First, bearing wear often causes noisy operation and reduced airflow. Therefore, monitor vibration and replace bearings proactively. Second, clogged filters reduce airflow and force fans to run at higher RPM, which shortens life. Consequently, schedule filter cleaning and replacement. Third, improper voltage or uncontrolled inrush damages motors. Therefore, protect circuits with appropriate fuses and soft-start measures.

Finally, contamination and corrosive environments shorten life. Therefore, choose high-IP fans or relocate cabinets to environmental enclosures where needed.

13. Quick selection checklist for engineers

Use this checklist to choose the right PHARPSFAN03000 variant:

-

Confirm voltage and control type (DC vs. AC, PWM).

-

Verify CFM and static pressure at installed conditions.

-

Select bearing type for runtime and vibration.

-

Check IP rating and material for environment.

-

Ensure mounting dimensions match cabinet slots.

-

Confirm tachometer or alarm outputs if monitoring is required.

-

Plan redundancy and control strategy (N+1, staged start).

-

Order spares and document part traceability.

-

Schedule verification tests and thermal soak checks.

-

Source from an authorized supplier with technical support.

14. Final recommendations

In summary, engineers should treat the PHARPSFAN03000 as a system component rather than a commodity. First, size airflow to the actual cabinet conditions. Second, factor in filter, duct, and altitude losses. Third, select bearings and environmental ratings to match your duty cycle. Finally, implement monitoring and redundancy for mission-critical cabinets. Consequently, you will protect expensive control hardware and avoid unplanned downtime.

For verified ABB parts and technical support, consider suppliers who specialize in industrial automation spares. For example, Wuhan Yuli Automation Technology Co., Ltd. provides PHARPSFAN03000 units, datasheets, and selection assistance. Therefore, you will complete procurement with confidence and traceability.