ABB SPDSI13 Module: Comparison Between Old and New Models

ABB SPDSI13 Module: Comparison Between Old and New Models

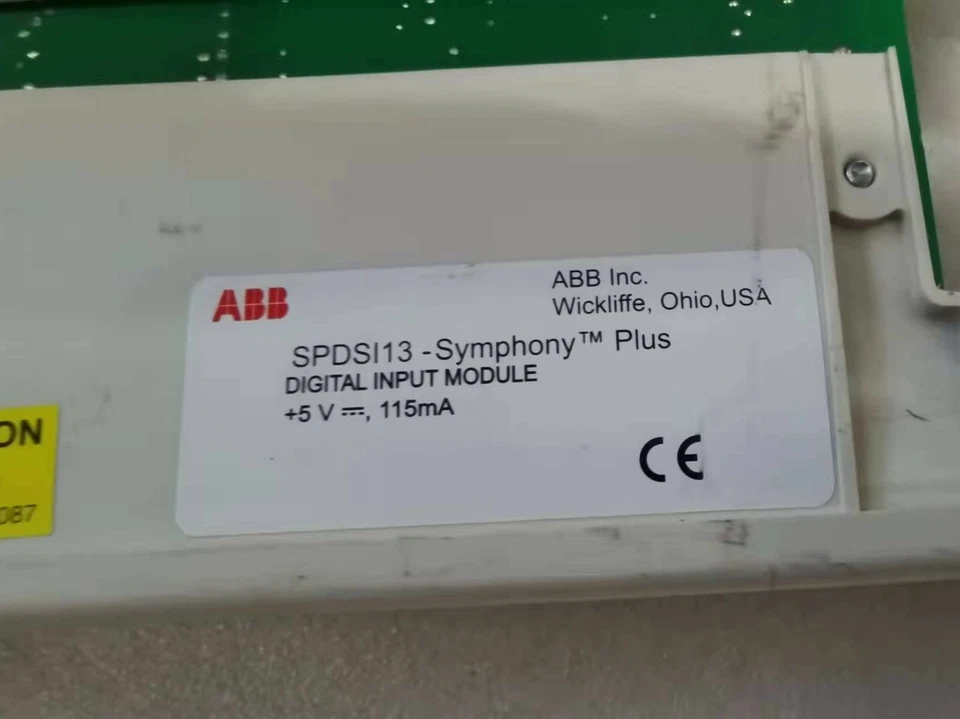

The ABB SPDSI13 module plays a critical role in industrial automation systems, providing reliable communication, precise I/O management, and seamless integration with ABB PLCs. Over time, ABB has released updated versions of the SPDSI13, improving functionality, reliability, and compatibility. Understanding the differences between the older and newer models is essential for engineers, system integrators, and maintenance teams to ensure optimal performance, minimize downtime, and maintain operational efficiency. This comprehensive guide explores specifications, performance improvements, maintenance considerations, and practical applications of the SPDSI13 module.

Overview of SPDSI13 Module

The SPDSI13 module is designed to handle both digital and analog signals, offering fast and accurate data processing. Its modular design allows easy installation in industrial racks, enabling quick replacements and upgrades. Key features include:

-

High-speed signal processing for industrial automation

-

Compatibility with ABB PLCs and automation networks

-

Compact and durable design for challenging environments

-

Flexible configuration for various industrial applications

This foundational understanding sets the stage for comparing old and new models effectively.

Evolution and Upgrades in SPDSI13

ABB continuously refines its modules to meet the growing demands of automation systems. The new SPDSI13 version includes several important upgrades:

-

Improved Data Accuracy: Reduced latency and enhanced signal processing.

-

Enhanced Reliability: Robust components and better thermal management.

-

Expanded Compatibility: Supports more PLC models and network protocols.

-

Simplified Maintenance: Easier access to connectors and modular design for quick servicing.

These upgrades address common issues in older models, such as communication errors, signal delays, and integration difficulties.

Technical Specifications: Old vs New SPDSI13

Comparing the technical specifications highlights the improvements in the newer SPDSI13 module:

| Feature | Old SPDSI13 | New SPDSI13 |

|---|---|---|

| Input/Output Channels | 8 DI, 4 AI | 12 DI, 6 AI |

| Response Time | 15ms | 8ms |

| Operating Temperature | -10°C to 55°C | -20°C to 60°C |

| Power Consumption | 12W | 9W |

| Network Support | Limited PLCs | Expanded PLC and protocol support |

| Maintenance | Standard | Modular, easy-access connectors |

These enhancements contribute to faster response, higher reliability, and lower operational costs.

Installation Differences

While both versions fit standard ABB racks, the new SPDSI13 emphasizes ease of installation:

-

Tool-less Connectors: Streamline installation and reduce human errors.

-

Enhanced Alignment: Ensures secure insertion and stable connections.

-

LED Status Indicators: Provide immediate feedback for diagnostics.

Technicians upgrading to the new module will benefit from improved ergonomics and faster deployment.

Maintenance Practices

Regular maintenance ensures long-term reliability. Recommended practices for SPDSI13 modules include:

-

Visual Inspection: Check for dust, corrosion, and loose connections.

-

Firmware Updates: Maintain updated firmware to enhance performance.

-

Environmental Monitoring: Monitor temperature, humidity, and airflow.

-

Cleaning: Remove dust with compressed air without touching sensitive components.

The new modular design allows faster access to components and reduces downtime during maintenance.

Common Issues and Troubleshooting

Even well-maintained modules may encounter issues. Common problems include:

-

Communication Failures: Often due to loose connectors or outdated firmware.

-

Signal Delays or Loss: Result from damaged cables, poor connections, or environmental interference.

-

Power Fluctuations: Can cause unexpected resets or malfunction.

-

Component Wear: Over time, connectors and circuits may degrade.

Effective troubleshooting involves checking power supply, verifying connectivity, updating firmware, and performing functional tests.

Real-World Applications

In industrial environments, SPDSI13 modules manage critical processes:

-

Automation Systems: Coordinate input/output signals across multiple PLCs.

-

Process Control: Ensure accurate measurement and timely responses.

-

Energy Management: Monitor power systems with precision.

-

Safety Systems: Facilitate reliable emergency shutdowns and system monitoring.

Comparing old and new modules in these applications shows significant improvements in reliability, efficiency, and integration.

Conclusion

The ABB SPDSI13 module remains a cornerstone of modern industrial automation. Comparing older and newer versions highlights improvements in speed, reliability, maintenance, and compatibility. Engineers and technicians can benefit from enhanced performance, reduced downtime, and easier system integration by adopting the updated module. Understanding these differences ensures operational efficiency, system stability, and long-term reliability in industrial environments.